Seam AuSn solder hermetic cover sealing is a resistance heating process to join the cover and seal ring. The cover is Kovar™ and seal ring is thick film on substrate, both with 1.27µ Au on top of 5µ electrolytic Ni plate. The 80Au20Sn solder is eutectic with moderate fluidity when molten. No forming gas is required. The solder preform is pre-tacked to cover for ease of manufacturing.

Seam AuSn solder cover sealing is easily viewed. The cover is placed upon the seal ring, only requiring gravity to maintain the fit-up of the two faying surfaces. There are no special jigs or fasteners required. Two opposing conical shaped electrodes roll along the perimeter of the cover and package seal ring. I2R heating will molten the solder and join the Au/Ni plated cover to package seal ring, forming a gas tight seal. Fine leak rates are typically one decade slower than welding.

Seam AuSn solder cover sealing provides precise control over the internal package atmosphere. There is low heat input to the device and internal structures during the cover seal process. Prior to the hermetic cover seal, the unsealed package is processed with a deep vacuum bake moisture removal process. Hermetic sealing is then performed in a controlled inert environment including H20 ppm, 02 ppm and 0.1µ particulate filtration.

In comparison to oven/belt furnace processes, MCL Seam AuSn Solder Cover Sealing process provides the lowest temperature exposure to your internal devices, lowest package assembly leak rate and most pristine internal microcircuit atmosphere. MCL Seam AuSn Solder Cover Sealing process will exceed Test Method performance per MIL-STD-883 for Microelectronics and MIL-STD-750 for Semiconductor Devices. AuSn Solder Cover Sealing process is available from prototyping to high production rates of several hundred packages per hour.

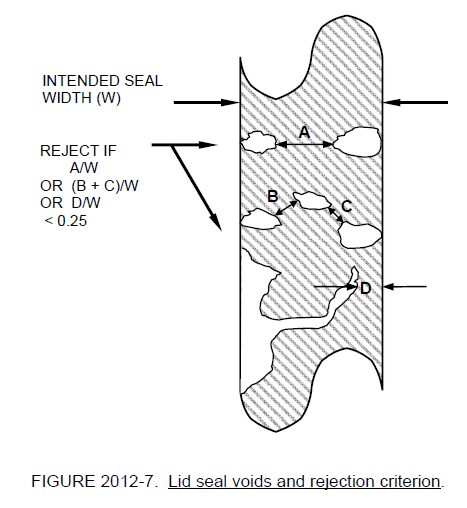

Ultra-small packages require the lowest solder voiding. With smaller seal ring width and solder preform widths, optimized mechanical strength is achieved with no voiding. With what remains from the interior chip and structures, the open interior volume of a hermetically sealed package is very small. Trapped gasses in a void could lead to contamination of this atmosphere.