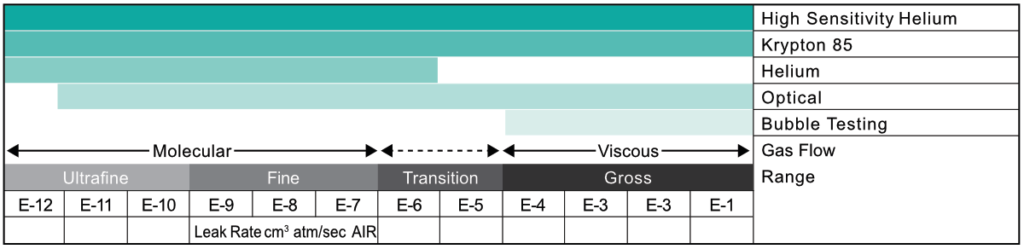

MCL develops automated viscous gross and ultrafine molecular leak rate testing processes to meet your specific package, feedthrough and production requirements. Our process uses a single, dry, automated method for capturing both gross and fine leak rates with multiple data points on each package’s leak rate during the entire testing sequence. Gross leakers will never result in false fine leak rates with an MCL process.

High Sensitivity Helium Leak Detection

Per MIL-STD-883 Test Method 1014 Seal, the A5 method utilizing High Sensitivity Helium Leak Detection provides both gross and fine leak testing in one system, enabling data points through the complete leak testing process. The leak detection system is calibrated to NIST traceable helium leak rate standards, which are corrected for use temperature and helium depletion rate. The helium signal is measured from each of the two corrected helium leak rate standards.

MCL’s manufacturing utilizes the Howl Mann Flexible method which enables multiple dynamic conditions to determine the leak rate readings. The Helium bomb termination is entered into the leak rate calculation so exact termination times are not required. MCL’s facility includes eight (8) helium bomb stations for simultaneous high-mix sealed package gross and fine leak testing. No gross leak bubble detection is required with the A5 method.