Hermetic Package Sealing Technology

Outsource Development, Prototyping and Test for Lowest Costs

- Lowest Temperature Device and Feedthrough Exposure

- Seam Weld & AuSn Solder Cover Sealing

- Automated Gross and Fine Leak Testing

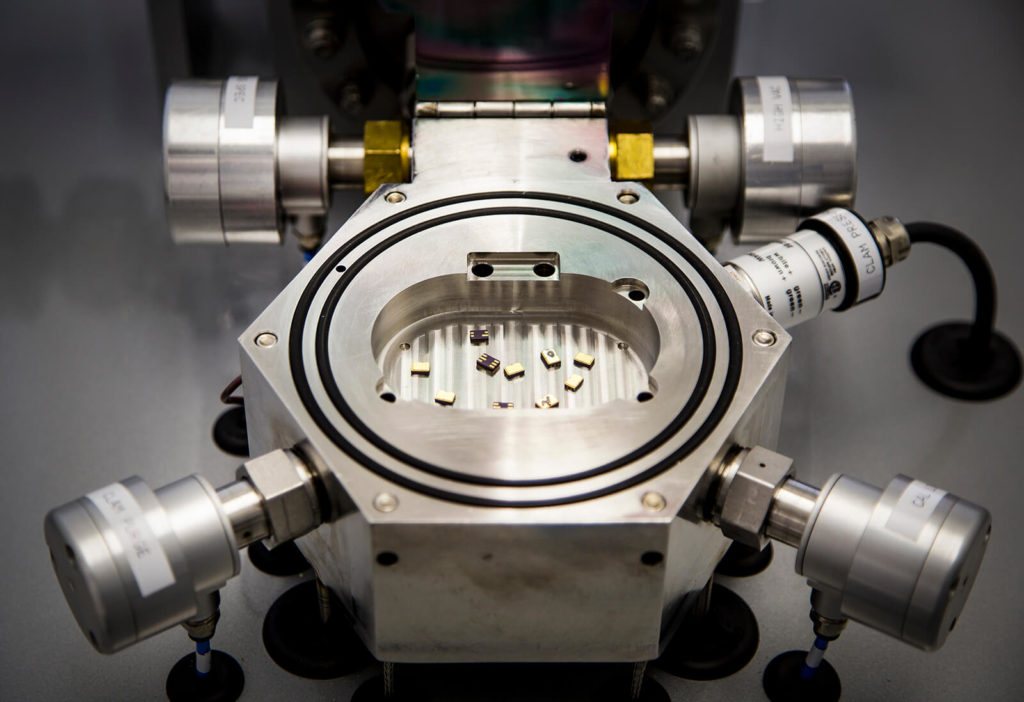

Experts in Hermetic Package Sealing

Since 2015, our mission is delivering the highest performance hermetic package sealing. New product development, prototyping or production line down resolution, MCL’s hermetic packaging services have you covered. Our class 10 cleanroom provides ultra-clean processing, from incoming inspection through hermetic cover seal. We fabricate tooling and capabilities including automated optical and digital microscopes, X-Ray, SEM with EDS, sample preparation including an ion mill, Seam Weld and Seam AuSn Hermetic Cover sealers in automated glovebox systems with deep vacuum bake, automated gross and fine leak testing, mechanical testing, internal vapor analysis.

MCL’s technical staff includes team members with 35 years + of hermetic cover sealing; metallurgist; semiconductor processing and manufacturing; MCL is fortunate to be located in the Brandywine River Valley of Pennsylvania which is abundant in human capital and suppliers.

Customized Development Solutions

- Photonics

- Opto-Electronics

- 5G Fiber Optic Communications

- MEMs

- Communications and Radar

- SAW

- Power

- GaN / Sic Power

- Flip Chip

- COTS

- Hi-Rel

- BGA

- Ceramic Quad Flat Pack

- Leadless Chip Carrier

- LDMOS

- MCM

- MMIC

Development

Production Services

Tailored production, following a defined process flow with project specific travelers, MCL provides production services with rapid turn times. The complete production sequence of the hermetic packaging sealing process and testing are performed on site. Test data may be provided by package serial number. All MCL equipment is on our internal only network for ease of data collection.

Customized Services to Suit Your Needs